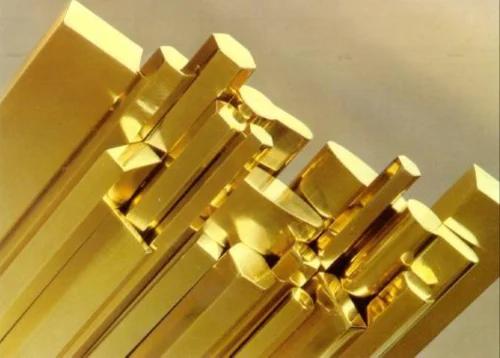

INDOFAB MANUFACTURES A WIDE RANGE OF ALLOYS

ROUND BARS

ROUND BARS

Hex bars

Hex bars

FLAT BARS

FLAT BARS

SQUARE BARS

AS EXTRUDED

CUSTOMISED BARS

Indofab Metpro Engineers LLP

RODS AND SECTIONS

Alloy range: Aluminium Bronze, Phosphor Bronze, Silicon Bronze, Manganese Bronze, Nickel Silver, Cupro-Nickel, Naval brass, High Tensile Brasses, Aluminium Brass, Free cutting & Forging Brasses, Riveting brass, Copper-DHP & ETP, Chromium, Tellurium and Cadmium copper. [Up to150mm dia] * Sizes subject to confirmation Shapes: Dia, A/F Hex, rectangular

TUBES, PIPES & HOLLOW RODS

Alloy range : Admiralty Brass, 70/30 Arsenical Brass/ ‘Sugar Brass’, Aluminum Brass, Naval brass, Leaded 60:40 Brass, 90:10 Cupro-Nickel, Silicon Bronze, Aluminium Bronze, Al Si Bronze, High Tensile Brasses of different composition, other Brasses. 70:30 Cupro-Nickel.

Custom Designed Alloys Can be made.

Size: Up to150mm dia OD * Sizes subject to confirmation

HEAT EXCHANGER :

Plain Tubes for heat exchangers, condensers and oil coolers. Alloys currently offered: Admirality & Aluminium brass, Aluminium Bronze and copper nickel.

Brass (70/30) arsenic inhibited, suitable for river and lake water where lack of severe corrosion conditions do not warrant the use of more expensive alloys.

Admiralty Brass (CuZn28SN1), Steam condensers & coolers for land based stations with brackish river waters slightly acid or alkaline. Also resistant to sulphur-bearing gases.

Aluminium Brass (CuZn20Al2), Extensively used material and one of the most popular. This alloy forms a protective film which has self-healing properties. This film is dependant on oxygen dissolved in the water and will not renew itself in polluted or stagnant water. High resistance to corrosion in clean seawater or in difficult land conditions .

Cupro Nickel Alloy (CuNi10Fe1Mn)

Widely used in condensers, coolers and heat exchangers where resistance to corrosion and erosion is paramount, yet maintaining a high thermal conductivity rate. To be used preferably in marine conditions. Forms a protective film which is multi-layered in flowing seawater. Resists marine befouling.

Cupro Nickel Alloy (CuNi30Mn1Fe)

Improved corrosion resistance and almost insensitive to stress corrosion, this alloy will give superior results in high velocity polluted water, including seawater. A reduced thermal conductivity level, but will retain its strength at moderately increased temperatures.

GENERAL ENGINEERING :

Tubes for General Engineering applications:

Brass tubes of CuZn::63:37 composition are widely used in a variety of applications across the cross section of engineering industries – Ordnance, Sanitary, Hardware, Automobile components, Radiators, Transmission antennae, Electrical, Furniture, Agricultural implements, Musical Instruments, etc….to name a few.

Excellent cold working polishing properties make it the best option for such applications.

Aluminium Bronze Tubes:

Widely used in corrosive environment for marine condensers, coolers and heat exchangers where resistance to sea water corrosion and erosion is paramount, yet maintaining a high thermal conductivityrate. To be used preferably in marine conditions.

Tubes for Synchronizer Rings:

Tube of Heavy Duty High strength & wear resistant Brass used for Brass synchronizer rings in a variety of alloys and compositions.

Can also be supplied as pre cut blanks within desired cutting tolerances suitable for forging applications.

Customised alloy tube options:

Available in various alloy categories with controlled elements for specific customer requirements .

* Size subject to confirmation

HOLLOW RODS

Leaded (60/40) Special Alloy Tubes :

suitable for Machinable quality Hollow Rods of Round/ Polygonal/ Square/ Rectangular outer shapes and Round Bores on Inner Dia in various size combinations most convenient and economical for Machined components with hollow centre in a host of industries and applications, viz- Automobile, General Engineering, Industrial Valves, Sanitary Fittings, Air conditioning & refrigeration, Electrical, Musical Instruments, Hardware and White Goods, and many more…

Leaded Special Bearing Alloy Tubes :

Special brass alloys in a variety of combinations made as per customer specifications suitable for all kinds of bearings and bushes. The materials possess high wear resistant properties best suited for Ball and Needle Roller bearing cages for Automobile, Engineering, and a host of other specialized applications.

Customized alloy Hollow rod options:

Available in various alloy categories with controlled elements for specific customer requirements .

* Size subject to confirmation